UT CIS Ready to Connect Manufacturers to Powerful Material Evaluation Equipment

The University of Tennessee Center for Industrial Services signed a contract this month with the UT Center for Materials Processing. Now small manufacturers can access essential technologies for nondestructive evaluation of manufacturing materials at the University of Tennessee. The new agreement makes it possible for companies to run a limited number of trials on advanced equipment without the need for additional contracts and payments. The Center for Materials Processing can provide access to a variety of imaging techniques including, optical microscopy, Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM). The center has access to X-ray Diffraction (XRD), thermogravimetric analysis (TGA) for determining important process parameters such as vaporization temperatures and mass fractions. Additionally, the center offers dry powder separators (sieves), lab scale grinders and differential scanning calorimetry (DSC) to dial in processes parameters.

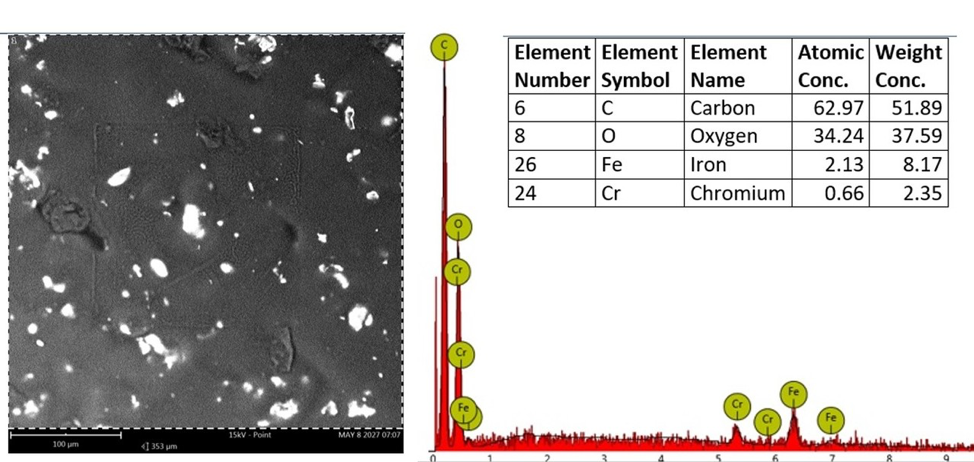

Claudia Rawn, Director and Chris Wetteland, Associate Director for Industrial Partnerships, at the Center for Materials Processing are leaders in their field and are supportive of industrial engagement. The photos above were taken using the UT CMP scanning electron microscope. The attached image of a 3D printed composite part identified elemental ratios of chromium, iron, oxygen and carbon on a 10 micron scale.

Do you have questions about your material content before, during or after processing? You can learn more about the equipment. As always, UT CIS is here to provide support for your manufacturing operation.